Find your career

Prepare for a wide array of career opportunities within advanced manufacturing and various other sectors:

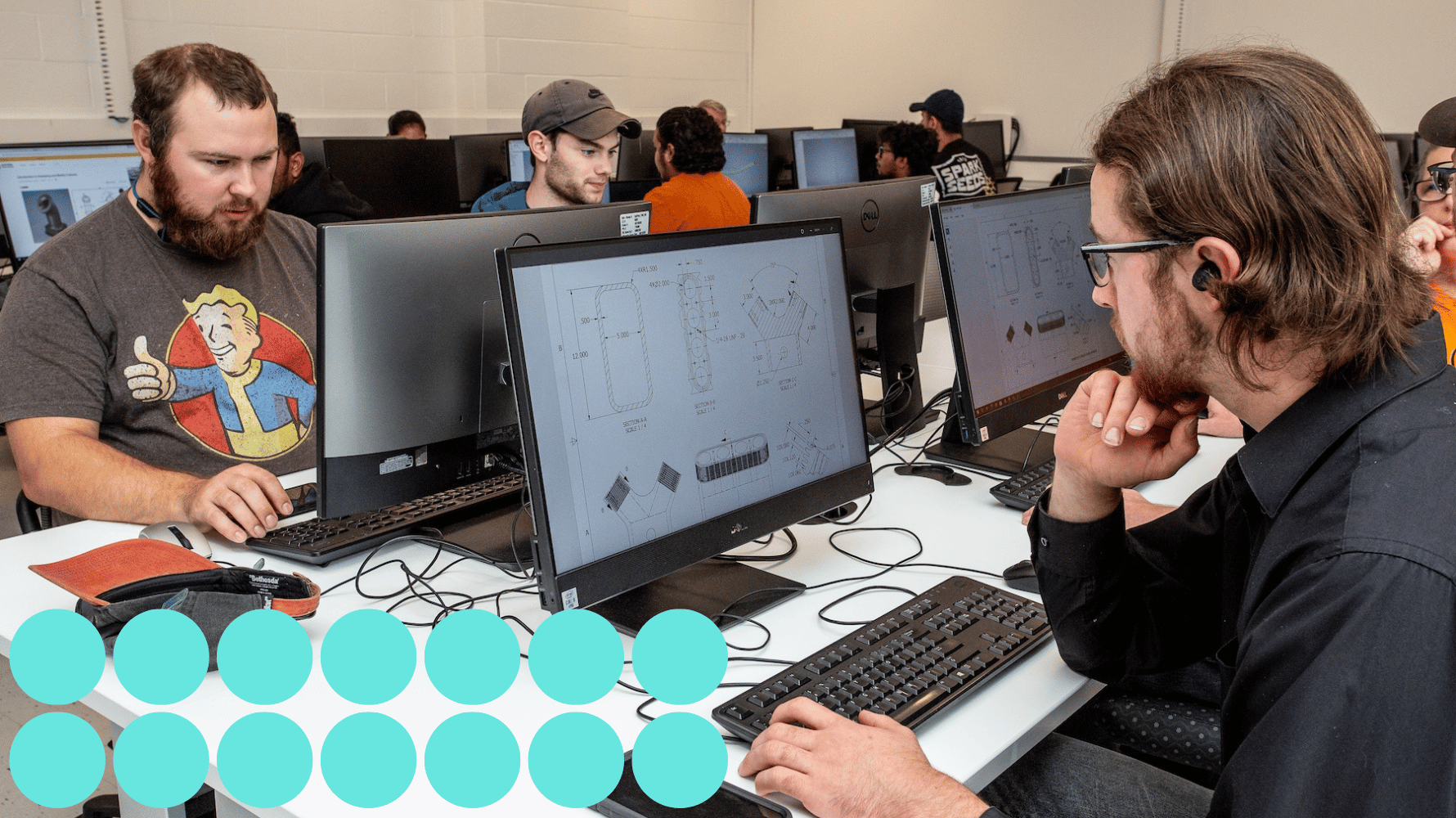

- Potential roles include positions in drafting and design, quality control, production supervision, and maintenance of production equipment.

- With skills applicable to both large and small organizations, graduates can find employment in sectors such as automotive, aerospace, consumer goods, and many other manufacturing environments.

- Graduates may also start their own businesses and become entrepreneurs.

Our grads get great jobs

- Project Manager, Research Castings International

- Owner, FDF Race Shop

- Sprinkler Fitter Technician, Onyx

- Field Fabrication Specialist, Atomic Energy of Canada Ltd.

- Machinist, Billet Precision Ltd.

- Engineering Technician, Beclawat Manufacturing Inc.

- Lab Technician, Magna

- Robotics Technician, Magna

- CNC Operator, Transformix Engineering Inc.

- Quality Control, St. Lawrence Cement Inc.

- General Machinist, The Machining Center

Is it for you?

A career in manufacturing is well suited to people who:

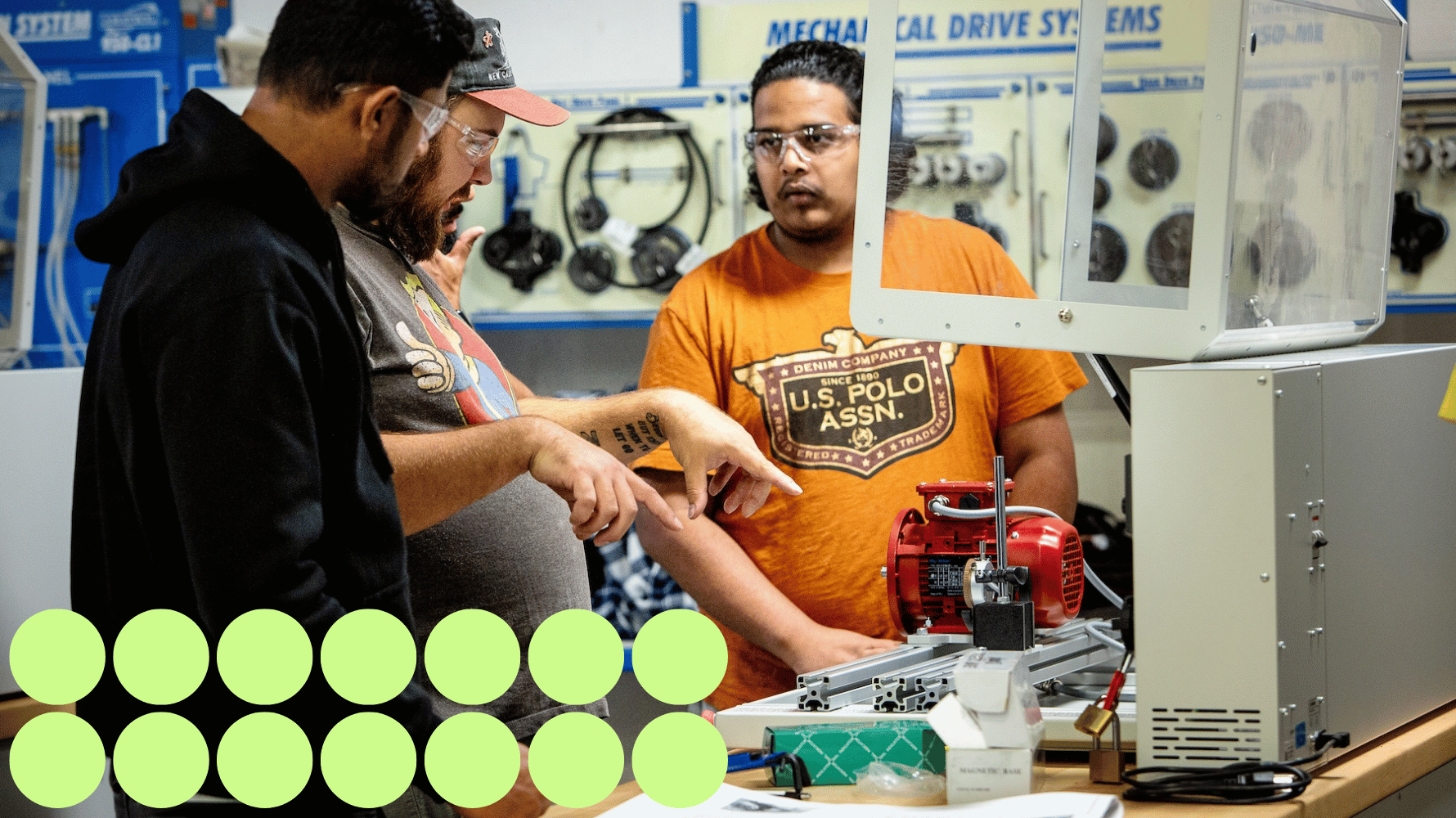

- Like to design and create

- Want to know how things work

- Enjoy working with their hands or repairing anything mechanical or electrical

- Would like a career where they can have a real impact on business

My program has prepared me by providing me knowledge about the industry. With my placement I have gained experience with new things.

Jagjit, Manufacturing Engineering Technician