Find your career

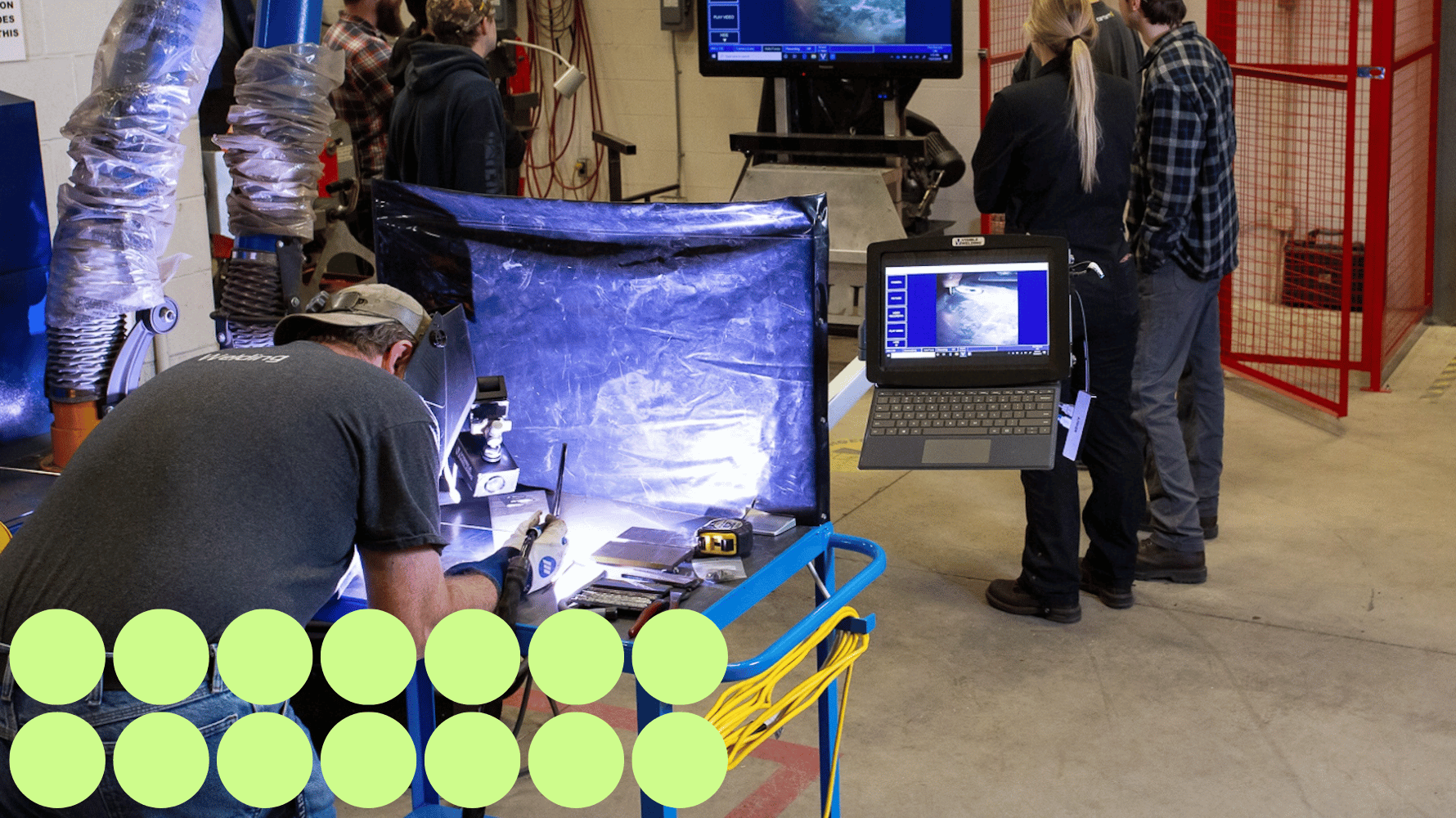

As a welder/fabricator technician, you will find job opportunities in any industry where metal fabrication and maintenance are performed. Your new skills can take you anywhere:

- You could work in manufacturing, construction, welding or inspection.

- Fabricate mining equipment; machinery; pipelines; bridge truss systems; vehicles such as subway cars and fire trucks; or shipbuilding and aerospace.

- Get an employment edge with certificates you can earn in the program, such as certified welder, structural steel plate fitter, certified welding inspector or welding supervisor.

- You could fast track into an apprenticeship.

Our grads get great jobs

- Technical Advisor, Voith Hydro Inc.

- Welder, Durose Manufacturing Limited

- Welder/Setter, L-3 Communications

- Welder/Fitter, North American Steel

- Level 2 Welding Inspector, Canadian Welding Bureau

- Thermite Welding, Canadian Pacific Railway

- Production/Welding, Honda Canada

- Welder/Fabricator, Material Handling Systems

- Welder/Fabricator, Timmins Trailers

- Welder/Fabricator, McCloskey International Ltd.

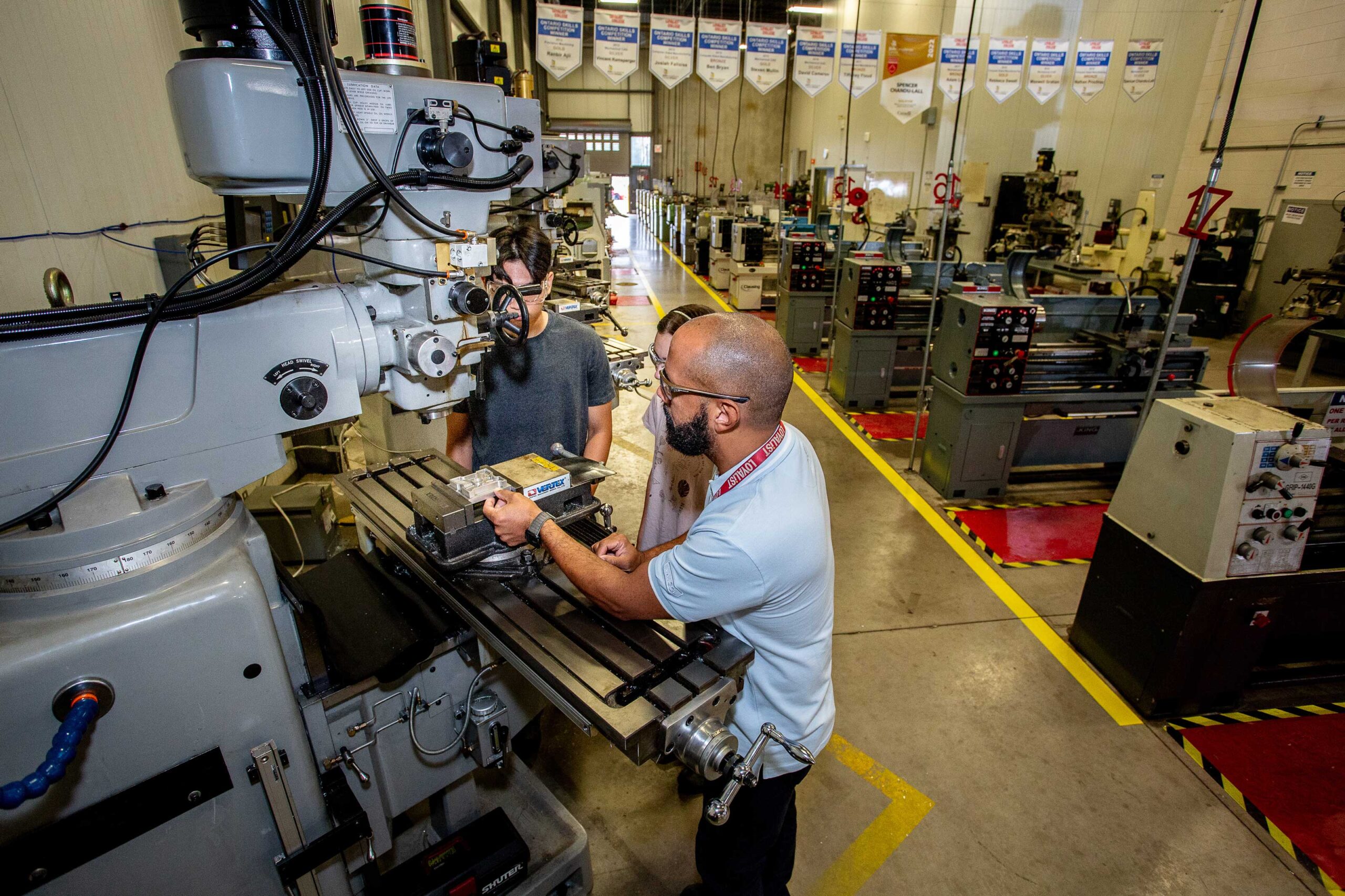

Is it for you?

Welders play an essential role in building and maintaining critical infrastructure. This is a good career for people who:

- Show precision in their work.

- Have solid math skills.

- Take pride in doing things right.

- Would like to master a skill that will be in demand wherever they go.