Ministry-approved program title: Electromechanical Engineering Technician – Mechatronics

Find your career

Graduates of this program may play an integral role in:

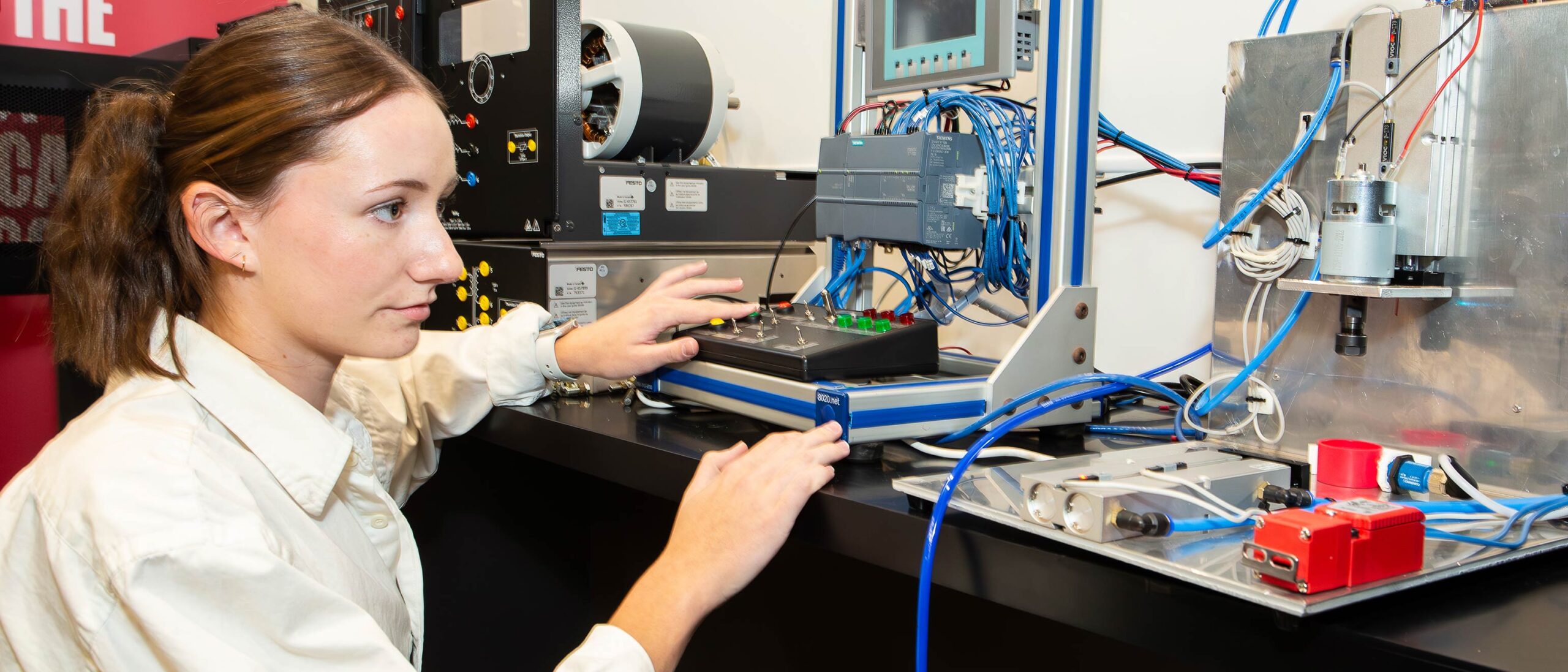

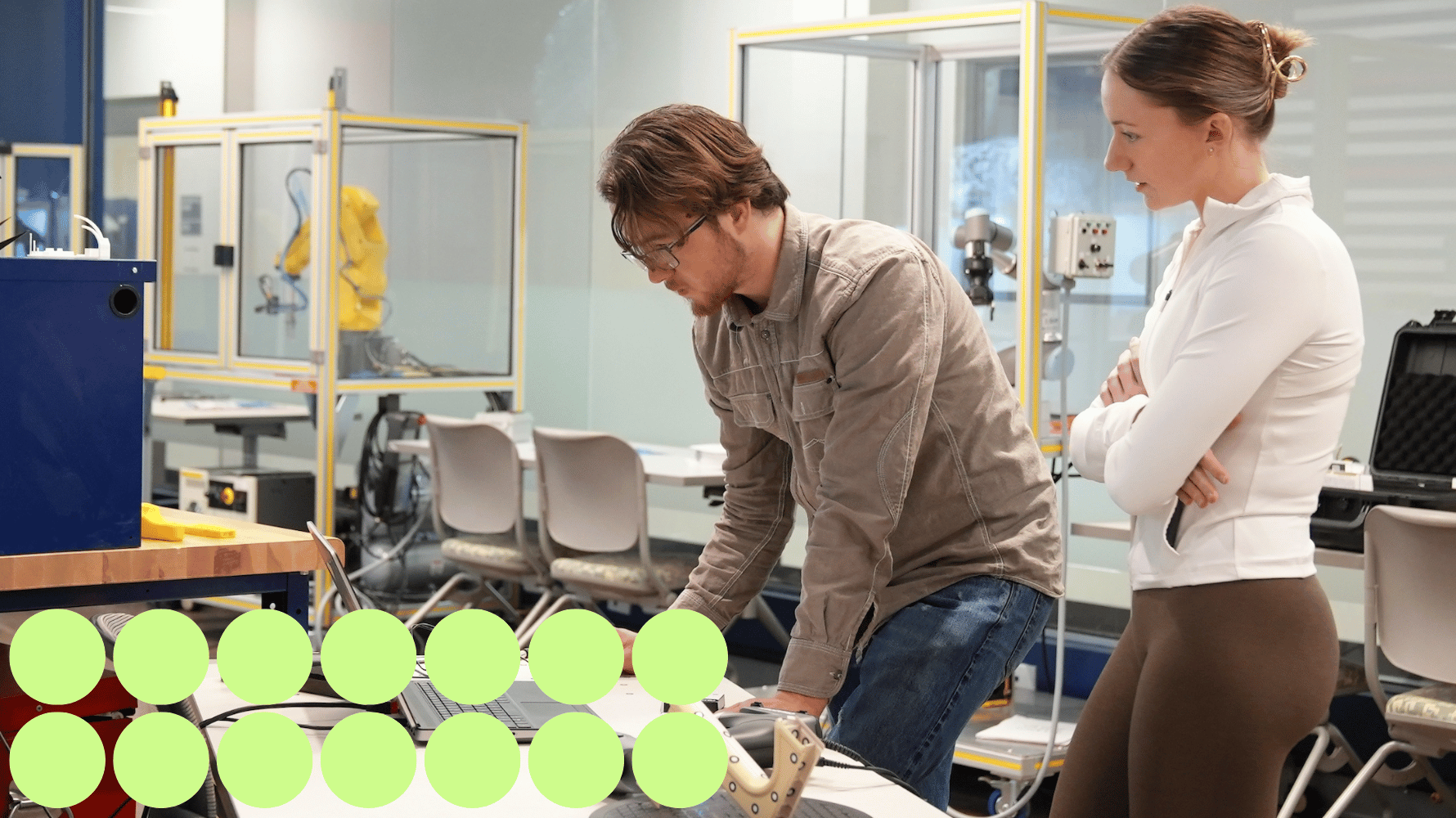

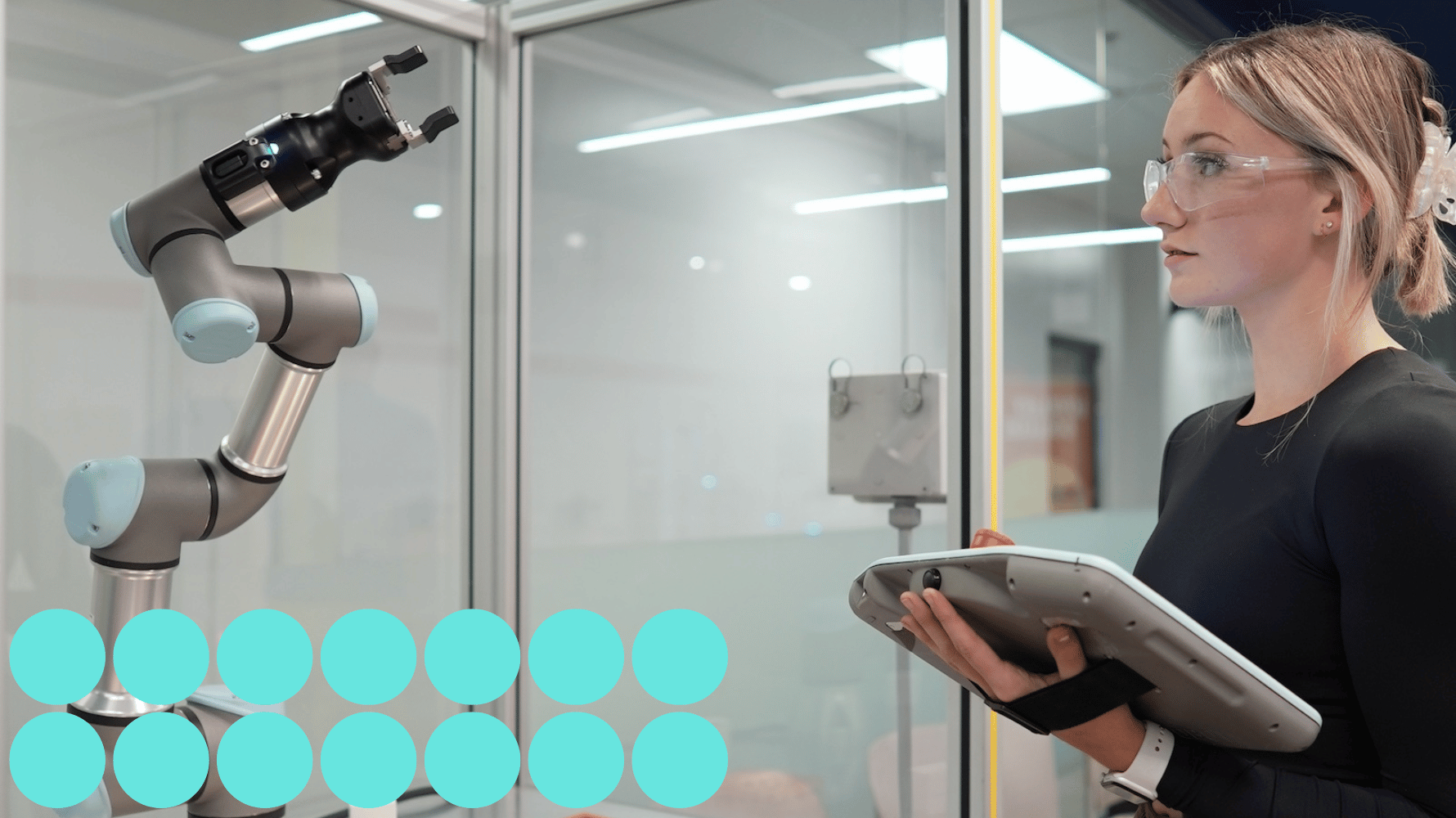

- Testing, installing and maintaining automated systems and robotics and electrical systems.

- PLC programming and implementation.

- Supporting computer and electronic goods production.

- Developing and monitoring equipment in manufacturing operations.

- Computer and electronics production.

- Installing and maintaining electrical systems.

- Wholesale trade in machinery and equipment distribution.

- Consulting across industries to support business and the public sector.

- Prototype development.

Is it for you?

This program holds rewarding opportunities for students who:

- Are drawn to knowing how things work.

- Enjoy creative problem-solving.

- Get excited about working with and learning about new technology.