Employers seek skilled workers who will help them to compete globally. Prepare to be in demand with a powerful combination of mechanical and electrical control skills that you can apply in any manufacturing career.

Find your career

There are many opportunities in large machine shops, manufacturing, design/build and food processing facilities.

- Work as a maintenance planner, performance lab coordinator, design verification technician, CNC programmer, CAD technician, PLC Programmer, mechanical designer, buyer, quality control or continuous improvement technician, or pursue a trades apprenticeship.

- Graduates work on fabrication and improvement of PLC-based equipment.

- Skilled manufacturing work is rewarded with above-average pay and benefits.

- Average entry-level salaries range from $40,000 to $44,999.*

*Source: Employment Profile Provincial Report, Ministry of Colleges and Universities.

Our grads get great jobs

- Field Fabrication Specialist, Atomic Energy of Canada Ltd.

- Machinist, Billet Precision Ltd.

- Engineering Technician, Beclawat Manufacturing Inc.

- CNC Operator, Transformix Engineering Inc.

- Quality Control, St. Lawrence Cement Inc.

- General Machinist, Sciens Industries Inc.

- Coating Operator/Manufacturing Technician, Indsale Ltd.

Is it for you?

A career in manufacturing is well suited to people who:

- Like to design and create

- Want to know how things work

- Enjoy working with their hands or repairing anything mechanical or electrical

- Would like a career where they can have a real impact on business

What employers say

“We’ve had excellent success hiring from Loyalist College. The students were completely prepared for our environment. The machines and controllers were very similar, if not the same, as what they were used to, and it was seamless. They came in, and within days they were set up and running CNC equipment.”

Gerry Vandersanden

President, Sciens Industries

“The calibre and quality of the graduates coming out of the Manufacturing Engineering Technician program at Loyalist are excellent. They come out with a huge leg up in terms of understanding the realities of a manufacturing plant.”

Ben Eby

General Manager, Beclawat Manufacturing

Click on the logos below to see the latest job opportunities:

DI COR Engineering

Experiential learning

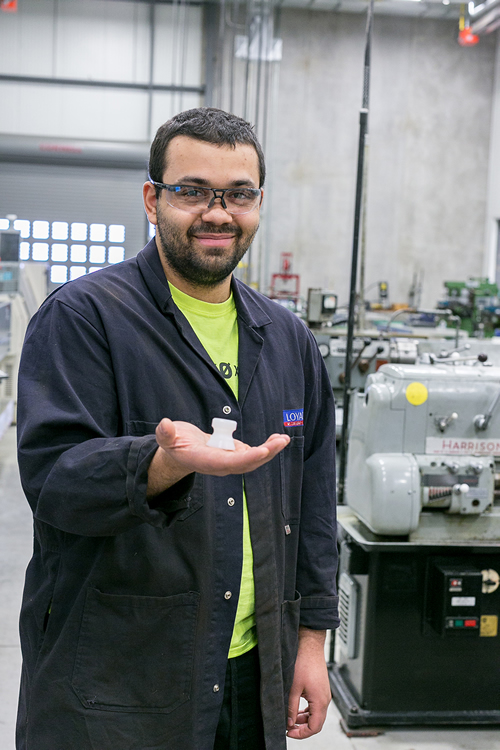

Learn hands on in Loyalist’s newly equipped The Bay of Quinte Skills Centre:

- Create projects on the latest CNC lathes, milling machines and 3D printing equipment.

- Use state-of-the-art Programmable Logic Controllers (PLCs) to control electromechanical systems.

- Create pneumatic and hydraulic circuits based on common industrial processes.

- Use welding processes to create projects.

- Design components using Autodesk Inventor, AutoCAD and CAD/CAM.

- Gain a deep understanding of machine and tool design, numerical control programming and statistical quality control.

Join our winning team!

- Bronze medal in the Computer Aided Manufacturing category at the 2019 Skills Ontario Competition – Nathan Prochnau

- Gold medal in the Computer Aided Manufacturing category at the 2018 Skills Ontario Competition – Rebecca Sweet (2018 graduate)

- Silver medal in the Mechanical CADD category at the 2018 Skills Ontario Competition – Maxwell Graham (2018 graduate)

- Silver medal in the Mechanical Computer Aided Drafting (CAD) category at the 2016 Ontario Technological Skills Competition – David Cameron (2016 graduate)

- Gold medal in the Mechanical Computer Aided Drafting category at the 2015 Ontario Technological Skills Competition – Steven Mullin (2015 graduate)

Outstanding faculty make the difference

- Learn in bright, well-equipped facilities with dedicated faculty.

- Professors have wide-ranging industry experience in machine shops, pharmaceutical manufacturing, food processing, water bottling, uranium processing and millwright contracting environments.

- The program coordinator is a Red Seal Industrial Millwright.

- Teachers have a vast network of industry contacts to help connect students with jobs.

After the first two semesters, students earn a certificate in Mechanical Techniques, and may progress into year two of the Manufacturing Engineering Technician diploma.

- First Year - Semester One

- MANU1009 Blueprint Reading 1

-

This course covers the theory, conventions, standards and procedures associated with the preparation of mechanical drawings. Orthographic drawings, pictorial drawings, sectional views, auxiliary views and principles of dimensioning are discussed to help students develop the skills to properly read blueprints. The course also introduces the student to computer aided design using AutoCAD.

- COMP1017 Computer Applications

-

Students are introduced to Microsoft applications such as Outlook (email), PowerPoint, Microsoft Word and Excel. Students learn how to use the Internet and understand the use of a maintenance management system. Within the course, students are equipped with job searching techniques, interview skills and will prepare a cover letter and résumé.

- MANU1006 Fluid Power 1

-

In this course students develop a clear understanding of the basic concepts of fluid power control systems. Students learn about the application of equipment such as pumps, actuators and control valves in detail, and develop a logical approach to the solution of fluid power control system design. Extensive hands-on labs reinforce the theoretical principles of fluid power.

- MECH1001 Machine Maintenance 1

-

Students are introduced to standard practices used in the inspection, dismantling and replacement of components such as bearings, chain and belt drives, and couplings.

- MANU1000 Machine Tools 1

-

Students will learn the basics of metal cutting using various machine shop tools including engine lathes, milling machines, drill presses, grinders, as well as various hand tools. Shop safety aspects and principles of metal cutting are discussed.

- SAFE1001 Occupational Health & Safety 1

-

Students learn the rights and responsibilities under the OHSA. Safety related to the uses of overhead cranes, forklifts, proper hook-ups lifting loads, and awareness to safety concerns within the industry are introduced.

- MATH1014 Technical Math 1

-

In this course, students demonstrate basic analytical skills and are prepared for further studies in mathematics. Topics include basic number systems and operations, basic algebraic operations and equations, units and measurement, and solving word problems.

- WELD1008 Welding 1

-

This course provides an introduction to the theory and practice of welding to give the student a strong background in various fabrication processes. Oxy-acetylene cutting, brazing, braze, soldering and Shielded Metal Arc Welding (S.M.A.W.) will be covered.

- First Year - Semester Two

- CADD1021 Blueprint Reading & CAD 2

-

Students learn the interpretation of installation, assembly and detail drawings as applied to the maintenance trade.

Prerequisite: MANU 1009

- ELEC1004 Electrical Fundamentals

-

This is a continuation of the first semester course with applications of AC theory to the installation and maintenance of motors and control systems.

- MANU1008 Fluid Power 2

-

A continuation of Fluid Power 1.

Prerequisite: MANU 1006

- MECH1006 Machine Maintenance 2

-

A continuation of Machine Maintenance as applied to air compressors, pumps, speed reducers and machine tools.

Prerequisite: MECH 1001

- MECH1004 Machine Tools 2

-

Students learn the application of turning, milling and grinding procedures to the repair of machine parts.

Prerequisite: MANU 1000

- MATH1016 Technical Math

-

Students consolidate skills in arithmetic, algebra, solving equations and geometry, trigonometry, and graphical analysis to solve problems used in technological applications.

Prerequisite: MATH 1014

- WELD1009 Welding 2

-

This course is a continuation from Semester 1 and furthers students’ knowledge of the application of standard welding processes to the repair and fabrication of equipment.

Prerequisite: WELD 1008

- GNED1100 Becoming a Global Changemaker

-

This Loyalist College graduate attributes course will help shape your perspectives, broaden your understanding of important issues affecting our societies today, and equip you with invaluable knowledge and skills that will inform your ability to influence your community in a meaningful and impactful way. By exploring topics such as cultural competency, Indigenous education, entrepreneurship, sustainability, health and wellness, and ecological literacy, you'll be equipped with a powerful toolkit that extends far beyond the classroom.

- Second Year - Semester Three

- CADD2002 CAD 3

-

This is a continuation of CAD 2 where more advanced techniques are introduced. Students learn to generate solids and wire from images using AutoCAD and CADkey software.

Prerequisite: CADD 1021

- MANU2011 CNC Machining

-

The objective of this course is to provide the student with the foundation of NC programming for turning and machining centres. The students will use computer aided methods to create NC programs and run the machine tools to produce a variety of components.

Prerequisite: CADD 1021

- MANU2010 Engineering Materials

-

The aim of this course is to show how and where ferrous and non-ferrous metals can be effectively and economically used. It comprises a study of the main properties, general composition, supply and methods of heat treatment. Ceramics, composites and other non-metallic materials are also discussed.

- MANU2009 Lean Manufacturing

-

This course introduces the learner to Lean principles and business processes. Businesses uses these principles to eliminate waste so that resources are used efficiently.

- ELEC3001 Programmable Logic Control

-

Students study programming, interfacing, applications and troubleshooting of programmable controllers. Emphasis is on hands-on learning and solutions to problems in industrial automation systems.

Prerequisite: ELEC 1004

- MANU2005 Quality Control

-

Students will learn how probability and statistics are applied to quality control as related to receiving and process control in manufacturing including how to sue and interpret various control charts for variables and control charts for attributes and sampling techniques. Other topics include process capability studies and improvement techniques such as Pareto diagrams and cause-and-effect diagrams.

Prerequisite: MATH 1016, CADD 1021

- GNED General Education Elective

- General Education Courses

- Second Year - Semester Four

- CADD2004 CAD 4

-

This course will instruct students in parametric design using the Autodesk Inventor software. Students will learn the best approaches to parametric design through hands-on practice in solid modelling, assembly, presentation, simulation and proper engineering drawing production. Also included in the course are sheet metal and weldment designs.

Prerequisite: CADD 2002

- CADD2003 Computer Aided Manufacturing

-

This is a continuation of CNC machining where students will learn to utilize CAD/CAM software such as MasterCAM to create part geometry within the software or import from a different CAD environment; they will create the tool path; verify it and generate the CNC code via a post processor for both mills and lathes. Students undertake progressively more complex projects including 3D solids from the design stage to and including actual setup and machining utilizing our industrial-type CNC machine tools.

Prerequisite: CADD 2002, MECH 1004, CADD 1021, MANU 2011

- MANU2007 Manufacturing Automation

-

Students will utilize modern automation technology to develop complex electro /mechanical systems. Students apply the principles learned in previous courses. The learner will apply safety protocol specific to the culminating project.

Prerequisite: ELEC 3001

- MANU2006 Mechanics and Machine Elements

-

The objective of this course is to provide the concepts and procedures required to design and select common machine elements, such as bearings, gears, belts, chains, etc. found in mechanical devices and systems.

Prerequisite: MATH 1016 or MATH 2008

- MANU2004 Tool Design

-

In this course, Students get a solid grounding in process planning and jig and fixture design. Through a variety of hands-on assignments, students will learn proper locating and work holding principles, become familiar with the type and purpose of a variety of different jigs and fixtures including modular fixturing. Students undertake progressively more complex jig and fixture designs and use CAD software to complete the designs including importing different tooling components from web sources such as Car Lane.

Prerequisite: CADD 2002, CADD 1021

- GNED General Education Elective

- General Education Courses

*Courses subject to change.

Turn your diploma into a degree

Many universities across Canada and abroad will provide credit recognition for your diploma studies at Loyalist College. The following is a list of agreements that are currently in place. There are many more options, and new agreements are added annually. Contact your university of choice to make individual arrangements. Click here for more information about university transfer agreements.

Two-year diploma

- Algoma University — B.A.; B.B.A.; B.Sc.; Bach. Computer Science

- Brock University — various*

- Davenport University – B.A. General Business

- Institute of Technology Tralee – Bachelor of Engineering in Manufacturing and Mechatronic Engineering (Year 3)

- Lakehead University — various*

- Laurentian University — various*

- Nipissing University — various*

- Queen's University — various*

- Ryerson University — various*

- Seneca College — Bach. Interdisciplinary Studies

- Ontario Tech University — various*

- University of Waterloo — various*

- University of Windsor — various*

- Wilfrid Laurier University — various*

- York University — various*

*Various potential degree pathways. Please confirm details with the receiving institution.

Study abroad

Explore opportunities to continue your studies in Ireland:

Autodesk certification

Students are eligible to challenge the Autodesk certification exams at Loyalist College. Completing these industry-recognized credentials enables students to highlight that they have the in-demand skills employers are seeking.

How much will it cost?

Approximate costs (2023 – 24)

- Domestic Tuition: $2,722.08

- Full-Time Ancillary Fees:* $1,308

- Total: $4,030.08

- Additional Program Costs: $1,200 (year one)

Additional costs, such as supplies, travel and parking, may be incurred during workplace visits, etc.

*Fees related to programs that are less than or greater than two semesters will be adjusted accordingly. Fees are subject to change. Please visit the Tuition and Fees web page for a list of the many services, activities and items included within the ancillary fees, and the related policies

Bursaries and financial assistance

Loyalist College has a number of scholarships, bursaries and academic awards available to students. Our Financial Aid Office can help you explore your options, or assist you with a student loan.

Students enrolling in this program may be eligible for the Schulich Builders scholarship program.

Schulich Builders covers tuition, tools and living expenses for students enrolling in a skilled trades program. Loyalist College will award ten scholarships per year:

- Five $20,000 scholarships for one-year certificate programs, and

- Five $40,000 scholarships for two-year diploma programs.

Admission requirements

Required academic preparation

- OSSD/OSSGD or equivalent with courses at the general, advanced, (C), (U) or (M) level, AND

- Grade 12 English (C) level or equivalent

- Applicants with a related certificate or diploma may be eligible to gain direct entry into year two (bridging courses may be required).

OR

Recommended academic preparation

- Grade 12 Math, courses in CADD, Chemistry, Manufacturing, Welding and Computers

Prior learning assessment and recognition

Applicants with work experiences or other types of non-credentialed learning may be eligible for credits at Loyalist. Graded credits (as opposed to exemptions) are granted. Click here for more information about our assessment and credit challenge process.

International students

Click here for information about how to apply, international student fees and more.

Campus News

LOYALIST COLLEGE ADDS SEVERAL DEGREE PROGRAMS THROUGH THE INSTITUTE OF...

Belleville, Ontario, May 31, 2018 – Graduates of six Loyalist College two- and three-year diploma programs now have the opportunity to earn a degree at the Institute of Technology Tralee, Ireland, ... Read More

Belleville, Ontario, May 31, 2018 – Graduates of six Loyalist College two- and three-year diploma programs now have the opportunity to earn a degree at the Institute of Technology Tralee, Ireland, ... Read More

LOYALIST COLLEGE MANUFACTURING STUDENT WINS GOLD AT THE SKILLS ONTARIO...

Belleville, Ontario, May 18, 2018 – Loyalist College is proud to announce that Manufacturing Engineering Technician students were awarded Gold and Silver medals at the Skills Ontario Competition ... Read More

Belleville, Ontario, May 18, 2018 – Loyalist College is proud to announce that Manufacturing Engineering Technician students were awarded Gold and Silver medals at the Skills Ontario Competition ... Read More

LOYALIST COLLEGE SKILLS COMPETITION WINNERS ANNOUNCED

Belleville, Ontario, March 9, 2017 – Loyalist College is pleased to announce the winners of the 2017 Loyalist College Skills Competition. Over 80 competitors from five school boards competed on Tue... Read More

Belleville, Ontario, March 9, 2017 – Loyalist College is pleased to announce the winners of the 2017 Loyalist College Skills Competition. Over 80 competitors from five school boards competed on Tue... Read More

LOYALIST MANUFACTURING STUDENT WINS SILVER AT OTSC

College Demos Automotive Virtual Reality Project and Wins People’s Choice AwardBelleville, Ontario, May 20, 2016 – Loyalist College second-year Manufacturing Engineering Technician student David C... Read More

College Demos Automotive Virtual Reality Project and Wins People’s Choice AwardBelleville, Ontario, May 20, 2016 – Loyalist College second-year Manufacturing Engineering Technician student David C... Read More

LOYALIST COLLEGE MANUFACTURING STUDENT PREPARES FOR SKILLS CANADA NATI...

[caption id="attachment_20591" align="alignnone" width="700"] At the annual Ontario Technological Skills Competition (OTSC), Manufacturing student Ben Bryan, left, earned bronze in the Computer Aided ... Read More

[caption id="attachment_20591" align="alignnone" width="700"] At the annual Ontario Technological Skills Competition (OTSC), Manufacturing student Ben Bryan, left, earned bronze in the Computer Aided ... Read More

In the News

Belleville Intelligencer

Belleville Intelligencer

Belleville Intelligencer

Belleville Intelligencer

InQuinte

InQuinte

Belleville Intelligencer

Belleville Intelligencer

Belleville Intelligencer

Belleville Intelligencer

Belleville, Ontario, May 31, 2018 – Graduates of six Loyalist College two- and three-year diploma programs now have the opportunity to earn a degree at the Institute of Technology Tralee, Ireland, ...

Belleville, Ontario, May 31, 2018 – Graduates of six Loyalist College two- and three-year diploma programs now have the opportunity to earn a degree at the Institute of Technology Tralee, Ireland, ...